Pozzi Leopoldo RCR EOP - heat recovery system

Tank Cleaning

Application

- Home /

- application /

- Tank Cleaning

Tank cleaning

Chemical tankers transport an enormous variety of chemical and oil products in global trade. Due to this variety the next cargo is almost never identical to the previous one. Thus, tank cleaning is essential with chemical, alimentary and product tankers. The products that need to be cleaned vary widely in their properties and characteristics. In addition, the chemical industry, the food industry, and their customers constantly increase quality requirements

Some cargoes require the use of a cleaning agent for efficient cleaning. Most cleaning agents are additives that are used in combination with water at high temperatures to improve the water solubility of the cargo to be cleaned.

Some cargoes require the use of a cleaning agent for efficient cleaning. Most cleaning agents are additives that are used in combination with water at high temperatures to improve the water solubility of the cargo to be cleaned.

The wash water, loaded with impurities, is normally drained at temperatures which are still quite interesting from a recovery point of view. It is, in fact, easy to conceive a system in which the hot drainage is fed

to an RCR before passing through the anti-pollution treatment plant. The energy contained in the drains can thus be transferred to the clean water entering the plant and be stored for future usage.

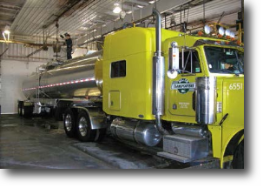

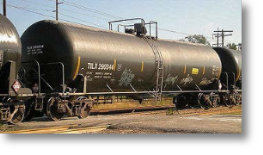

Most containers, such as truck tankers, movable IBC containers, railway tankers and so on,

need to undergo hot water-detergent or caustic treatment, thus a flourishing business

has grown around the need to thoroughly wash fowling containers.

The requirements are always the same: large quantities of very hot and filthy water that need to be drained, which is exactly the ideal environment for an RCR - RHeX

The requirements are always the same: large quantities of very hot and filthy water that need to be drained, which is exactly the ideal environment for an RCR - RHeX