The heat recovery solution to avoid heat exchanger fouling

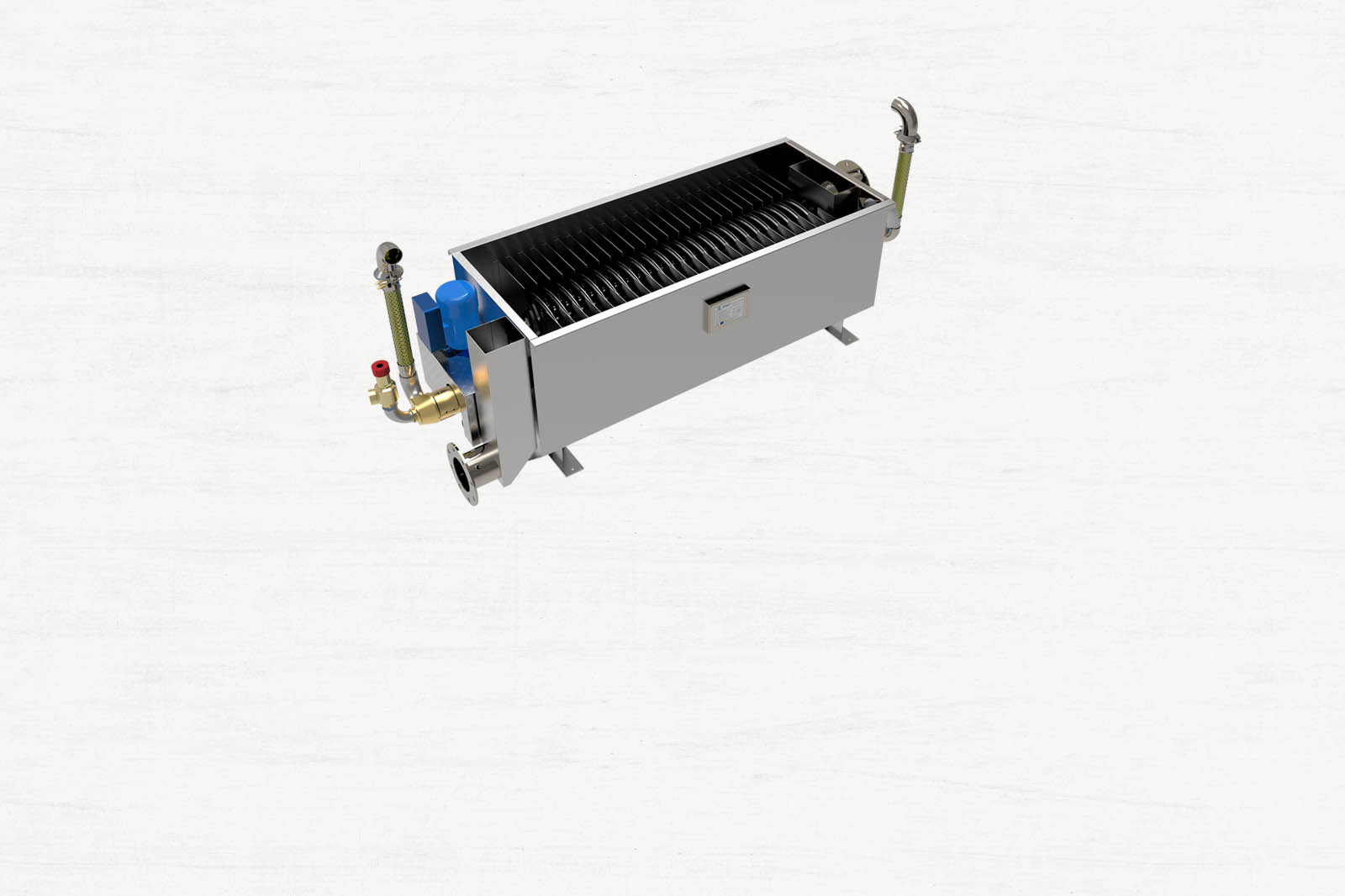

RHeX INDUSTRIAL HEAT EXCHANGER

Request info

Industrial heat exchanger

RHeX is an industrial heat exchanger, with the characteristic of being able to avoid what is normally referred to as heat exchanger fouling.

"Fouling is the accumulation of unwanted material within a processing unit or on the on solid surfaces of the unit to the detriment of function."

Heat exchanger fouling refers to what usually occurs when using a water heat exchanger in applications that treat discharges, effluents or fluids with “troublesome” properties*, which, by nature, contain mechanical or biological pollutants, which would normally stick to the surfaces or even clog up the passages of traditional types of exchangers.

*(e.g.: high presence of suspended solids or patinas/ biofilm creation on surfaces).

RHeX’s approach to the issue is completely different from all other industrial heat exchangers. The exchanging element of RHeX is in fact a rotor which rotates inside of a trough.

RHeX: POZZI’s water to water heat exchanger technology

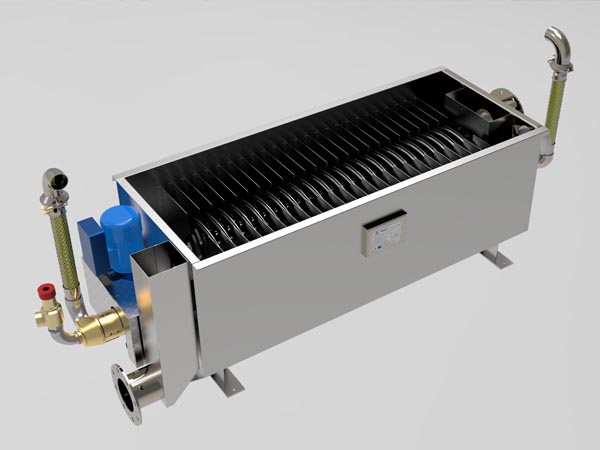

The “dirty” fluid will flow outside of the rotor (inside the trough), and will be subject to a very low-pressure loss. In fact, gravity will be the sole force used to push this fluid through the water heat exchanger. This fluid can be highly polluted even with mechanical impurities.

A secondary fluid will flow inside the rotor, counter current to the “dirty” fluid. This fluid must be free from mechanical impurities which might remain trapped in the rotor due to the separating effect of the centrifugal force generated during rotation. Pressure loss in this case will be dependent on RHeX model, flow-rate and rotational speed.

The hot discharge water (primary fluid) which can be contaminated with both chemical and physical pollutants, coming from tanks or directly from discharges of continuous machines, is introduced (as much as possible with a constant flow-rate) in our industrial heat exchanger, through flanged connections.

The flow of discharge waters runs through the tank using gravity only (the height difference between inlet and outlet) and it flows around the rotor by means of especially shaped deflectors.

The fresh clean water (secondary fluid), coming from the hydraulic network at a max. pressure of 4.5 bar, is fed inside the rotor through the flexible manifold and the rotating joints. The rotor is made of many shell-shaped elements, inside which a canalisation is created so that water circulates in a perfect counter-current flow running against the discharge water.

The rotor is activated by an inverter-controlled moto-reducer; the speed of the elements inside the water causes a turbulent movement, which increases the thermal exchange efficiency and avoids the physical pollutants deposit on the exchanger walls (better known as heat exchanger fouling).

The clean water, after having run across the rotor, exits from the opposite rotating joint as heated water.

The discharge water, on the contrary, has been cooled off since it has transferred its thermal content to the fresh water. The two circuits have fully opposite, counter-current directions, so to optimize the thermal exchange.

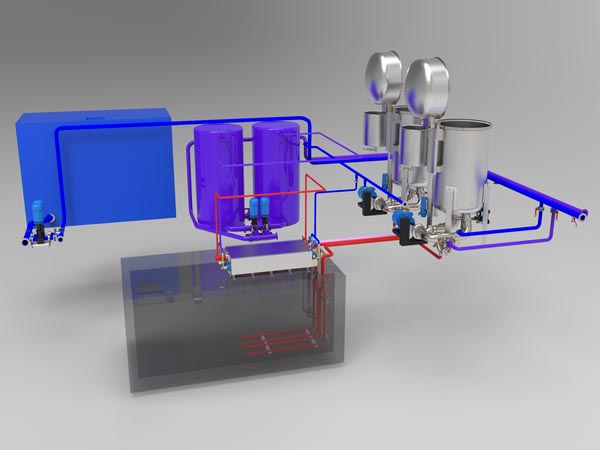

This water to water heat exchanger can also be used as a heating device (see an example here http://www.pozzienergy.it/application/ceramics/), making sure that the clean heating medium flows inside the rotor while the contaminated fluid flows inside the tank. Or alternatively as a cold recovery unit (see an example here: http://www.pozzienergy.it/application/food---beverage/chicken-processing-plants/).

Heating medium can be water or other fluid with no solid content and with a maximum temperature of 98°C.

Under special circumstances, low-pressure steam or overheated water can be used as a heating medium considering that, in this case, the maximum allowed pressure is 0.5 bar.

If used within its design restraints, a RHeX can be considered as an industrial heat exchanger with an unlimited lifetime, since, even if any component happens to fail at any point of its life cycle, it can be easily replaced and resume regular working conditions. Even if a disk of the rotating heat-exchanging element would fail, with the new design of RHeX, it is possible to simply remove it from the rotor and change it with a brand new disk.

RHeX: why our technology avoids heat exchanger fouling

The principle our RHeX water heat exchanger is to guarantee a high and constant efficiency of operation even when working with “troublesome” fluids. In traditional industrial heat exchangers, working with fluids that contain mechanical pollutants, chemical agents of any sort of anyway material that can either deposit in the exchanger itself or otherwise create patinas or biofilms, the problem know as heat exchanger fouling can be noticed.

Our technology instead, is focused on avoiding at all costs this issue.

Furthermore, the centrifugal force created makes it impossible for any material to deposit on the discs. The discs themselves are also electro-polished; this, with the added centrifugal force applied, makes it virtually impossible for patinas to be created.

Consider also that, given the nature of our water heat exchanger, we are able to concentrate a lot of heat exchanging area in a very short distance. As a matter of fact, if compared to a shell and tube industrial heat exchanger, RHeX has on average 18 times the heat exchanging area per meter of a traditional shell and tube exchanger.

RHeX ENDORSING

RHeX is an acronym that stands from Rotating Heat eXchanger. It is the newest generation of revolutionary industrial heat exchangers produced by POZZI. The technology was designed and patented by POZZI in the late ‘80s / early ‘90s and was initially called RCR (Recuperatore di Calore Rotante which is Italian for Rotating heat exchanger). Throughout the years our technology has gradually been updating, and in 2017 the European Commission co-founded the development of our latest upgrade (RHeX) as part of an HORIZON 2020 project called LOW-UP (grant agreement #999nonsoinumeri999).

In 2019 RHeX has been recognized by SOLAR IMPULSE Foundation as one of the 1000 world innovations that are both focused on the environment as well as profitable for the end-user.

In 2020, the European Commission's Innovation Radar has recognized POZZI as a “Key Innovator” for the development of RHeX and its technology.

Video demonstration

RHeX Rotating Heat exchangers

.

RHeX in Poultry Industry

RHeX in the ceramic Industry

RHeX robot welding

Pozzi RCR / EOP

About us

POZZI LEOPOLDO SRL

Well-established among textile machinery manufacturers worldwide, in recent years POZZI LEOPOLDO have moved from the historical century-old factory in Agliate to new premises in Barlassina, corresponding to the spirit of renovated enthusiasm that POZZI put in their activity.

Since 1885 ... expertise and energy for the future.

POZZI LEOPOLDO

Contact us to request more information

We will be pleased to better explain to you the machine and provide you with data and Expected Performance calculations for your application.

Contact info

Via Paganini 14

20825, Barlassina

Monza e della Brianza

Italy

Call: +39 0362 90811