The heat recovery solution for (troublesome) dirty fluids

RHeX ROTATING HEAT EXCHANGERS

Request info

Dirty and waste water heat recovery

There are many industrial and civil applications which, as part of the process, either work with or discharge as waste “dirty” or mechanically polluted liquids. In most cases, these liquids have been previously heated and still hold potential energy in the shape of thermal energy.

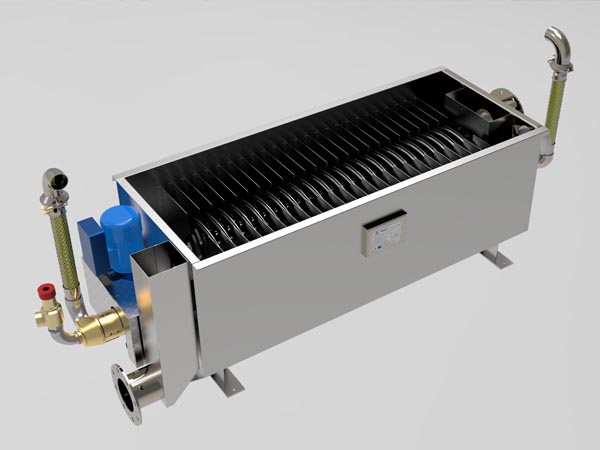

Normally, traditional type of heat exchangers (shell and tube, plate, pipe in pipe etc.) tend to clog, foul or otherwise lose efficiency when processing dirty fluids, as they are not suited for dirty water heat recovery from mechanically polluted effluents. Our patented solution can fill this gap by being able to harvest energy from fluids with high levels of mechanical impurities since, by holding a constant rotation of the exchanging surfaces (the discs), is able to keep itself clean, thus maintaining a constant efficiency. RHeX is not just a heat recovery unit, it is to all effects a waste heat recovery unit.

RHeX Rotating Heat exchangers

RHeX is a heat exchanger specifically designed to work with dirty and polluted liquids. Our patented solution, which has been co-founded by the European Union (European Union’s Horizon 2020 Research and Innovation Program under Grant Agreement n°723930) and has been recognized internationally by the Solar Impulse Foundation as well as the European Commission's Innovation Radar.

The requirements

The unit is completely self-cleaning. There are no tubes nor filters to be cleaned. RHeX is a modular system, which makes it ideal for placing in small spaces and does not interfere with the process. It is installed very quickly with a limited amount of piping involved..

Dirty and waste water heat recovery

Application examples

Pozzi Leopoldo has designed and built a self-cleaning heat exchange unit, which has become extremely successful throughout the world over the last decades. MADE ENTIRELY IN STAINLESS STEEL 316L, the heat exchanger has a central exchanging element rotated continuously by a small motor.

Textile finishing machines

In textile finishing machines, a constant flow of water is supplied and heated in the machine itself. Once utilized this water, which is now polluted, is discharged continuously. Here RHeX is used as a dirty water heat recovery unit, as it will use this polluted water, usually containing also fibres and filaments, to preheat the clean water that will be supplied to the machine.

More information on continuous installations such as textile finishing: http://www.pozzienergy.it/application/application-notes/performance-data/

Dye Houses

In textile dye houses, machines are supplied with water in batches for dyeing of threads, of garments or of raw material. The current technology for dyeing considers a number of “baths” for a single dyeing process, usually at temperatures that range from 40°C to 135°C (depending on the material). Once discharged, the water used will not only contain all the chemicals used for dyeing/washing/bleaching of the material, but also mechanical pollutants from the material itself (e.g.: fluff, fibres etc.). RHeX can use this discharge as heat recovery water without any issue, as even when working with large amounts of fluff (e.g.: terry towel), our waste water heat exchanger will still achieve a high and constant efficiency, without ever clogging.

Furthermore, it needs to be considered that in discontinuous applications such as this, the water is heated directly in the machine. A heat recovery unit such as RHeX, which can easily maintain a constant high efficiency, not only will produce savings in energy costs, but in these application it will also save a considerable amount of time, as a notable amount of time normally used to heat the water in the machine will not be necessary anymore.

For more information on discontinuous installations:

http://www.pozzienergy.it/application/application-notes/general-information--fitting-rhex---rcr-to-discontinuous-streams/

Industrial laundries

Industrial laundries normally need to wash high volumes of material such as hospital sheets and equipment (scrubs, towels etc.), Hotel and hospitality sheets and towels, factory uniforms etc.

The washing water, once discharged, will contain lint, fibres and any loose excess material as well as the chemicals used for washing, which have been contaminated by the dirtying elements present on the washed items (hair, grease, dirt, powders etc.).

The washing is done with high temperature water (60°C), as all these environments require to sanitize the material involved.

It is therefore very important to consider using the washing discharged dirty water for heat recovery, as this will equate to visible savings in energy costs.

Our patented waste water heat exchanger can easily treat this polluted water, avoiding any clogging or fouling, while maintaining a high and constant efficiency.

More on industrial laundries here:

http://www.pozzienergy.it/application/industrial-laudries/

Jeans Finishing

Denim, once made in garments, normally requires finishing. The process, which is also referred to as denim washing, has the scope of both creating a sturdier yet more comfortable feel, as well as aesthetic reasons. As a matter of fact, with the use of either stones, sands or enzymes, as well as a controlled pH of the bath, it is possible to create the effect known as “washed denim”, which has different results depending on the specific elements and acidity levels used. Depending on the type of “wash” wanted, the machines utilized for these processes will require water at different temperatures, but in all cases the water used will be warm (up to 60°C). RHeX is the only option for waste heat recovery from the discharges of these machines, since it will not only never clog, but will also work with higher efficiencies if compared to traditional heat recovery units.

For more information on discontinuous installations: http://www.pozzienergy.it/application/application-notes/general-information--fitting-rhex---rcr-to-discontinuous-streams/

Tanneries

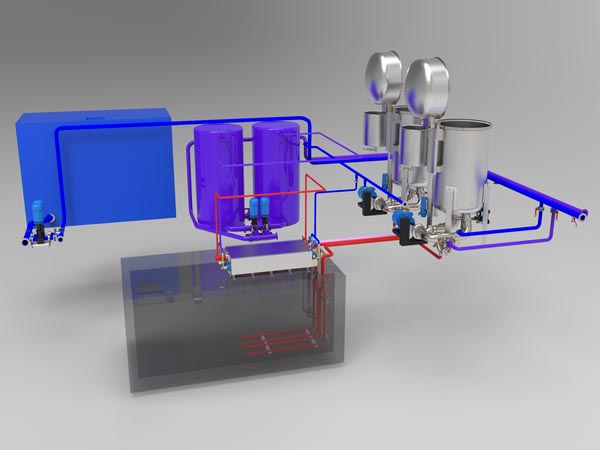

Usually, dirty water discharges in tanneries are mixed in a single rather low temperature stream (30-40°C) and contain a large amount of mechanical pollutants. RHeX waste water heat exchangers, in combination with heat pumps, can make use of this dirty water low enthalpy energy content and produce clean pre-heated water for the process making the tannery virtually steam-free.

The overall coefficient of performance of this type of waste heat recovery is extremely attractive making the investment profitable

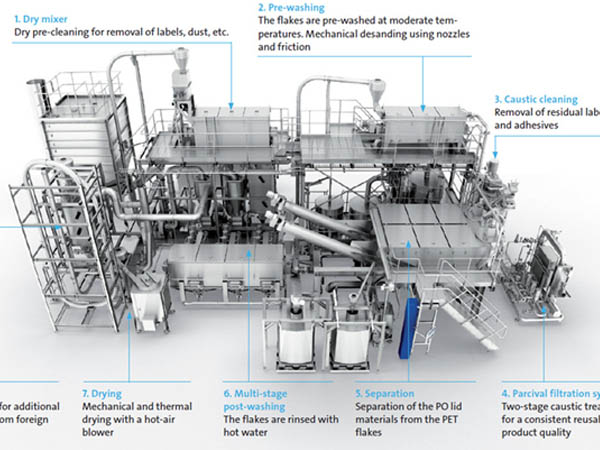

PET Recycling

The process of Polyethylene terephthalate (PET) plastic recycling starts with washing of the material that needs to be recycled before being minced and then treated. The discharge of this high temperature washing process is dirty water and contains mechanical pollutants such as labels and troublesome pollutants such as glue.

In traditional heat recovery units this fluid would be likely causes of fouling and clogging.

In order to recover this otherwise wasted heat, RHeX technology has been successfully applied to use this discharge for dirty water heat recovery and produce pre-heated clean water to be used in the same process.

Poultry De-Feathering

In some environments, instead of having to recover heat, it is necessary to recover “cold”.

An example is in poultry de-feathering plants, where chickens, after having been de-feathered, need to be cleaned. This process is done with water at 4°C. A heat recovery unit can be used in these environments so to pre-cool the clean water that will be fed to the process by “recovering” the cold from the discharge. An exchanger capable of dirty water heat recovery here is particularly useful as all the contaminants present in the effluent (feathers, bodily fluids and, most importantly, the high amount of grease) can easily be treated by RHeX without losing efficiency.

In the food business, the same can be applied to fisheries where the dirty water coming from the gutting line can be used to pre-cool the incoming fresh water.

More on this application here: http://www.pozzienergy.it/application/food---beverage/chicken-processing-plants/

Tomato & Nuts Peeling

Both tomato and nut peeling are processes where the peel of the product is removed during a hot flash steam - wash process. The discharged hot water will always contain all the peels removed from the product. Using this effluent as heat recovery water is very problematic with traditional heat recovery units. The design of RHeX allows any effluent containing mechanical pollutants such as peels to flow freely in the exchanger, without running the risk of clogging it, making it an ideal waste water heat exchanger.

More on this here: http://www.pozzienergy.it/application/food---beverage/nuts-peeling/

Latex glove production

RHeX is used as a dirty water heat recovery unit in latex glove production.

The intermediate and final wash in gloves production contain large amounts of extract proteins which quickly foul traditional exchangers. RHeX waste water heat exchanger performs with constant efficiency closing the energy loop in this process.

More information here: http://www.pozzienergy.it/application/industrial-cleaning/latex-gloves-production/

Ceramics

Since 2018 RHeX has started to be used in plants for pre-heating of “slip” in clay tile manufacturing plants. It can be considered the only type of exchanger able to perform with this extremely troublesome fluid.

Its use in this particular application has been patented.

More information here:

http://www.pozzienergy.it/application/ceramics/

Video demonstration

RHeX Rotating Heat exchangers

.

RHeX in Poultry Industry

RHeX in the ceramic Industry

RHeX robot welding

Pozzi RCR / EOP

About us

POZZI LEOPOLDO SRL

Well-established among textile machinery manufacturers worldwide, in recent years POZZI LEOPOLDO have moved from the historical century-old factory in Agliate to new premises in Barlassina, corresponding to the spirit of renovated enthusiasm that POZZI put in their activity.

Since 1885 ... expertise and energy for the future.

POZZI LEOPOLDO

Contact us to request more information

We will be pleased to better explain to you the machine and provide you with data and Expected Performance calculations for your application.

Contact info

Via Paganini 14

20825, Barlassina

Monza e della Brianza

Italy

Call: +39 0362 90811